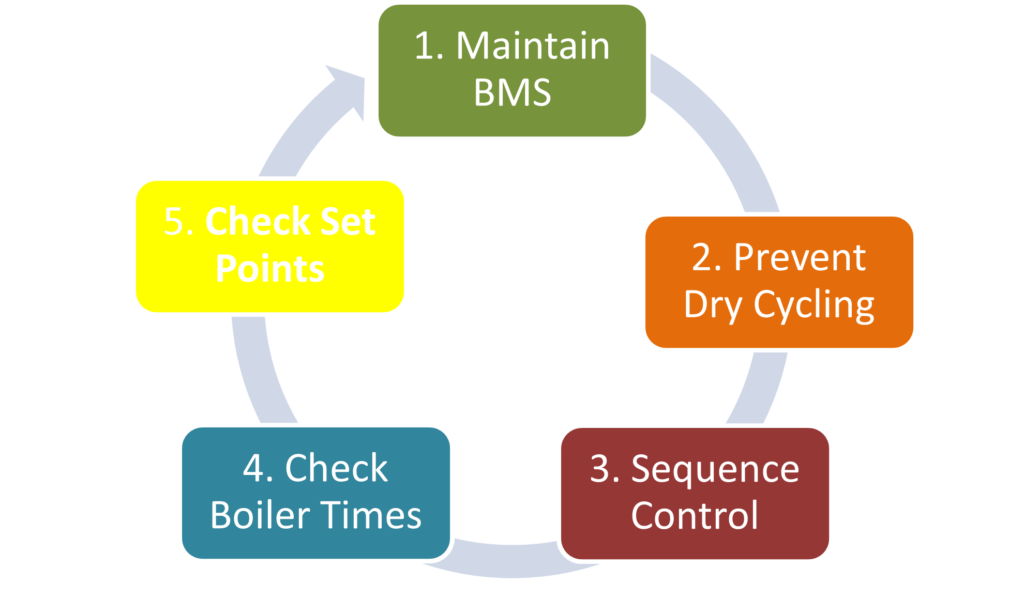

- Maintaining the BMS

Building Management Systems or Building Energy Management Systems (BMS/BEMS) are pivotal to maintaining the efficiency of a building and they need regular and planned maintenance. As building usage and occupation density change, so to do the control requirements for the heating system and this needs to be reflected in the BMS configuration.

For example, the BMS PC terminal needs to be constantly reviewed and sensors require regular re-calibration, otherwise you will see readings that don’t reflect the reality of the situation.

Sequence the boilers

Most boilers operate at their maximum thermal efficiency at 80% of the boiler firing capacity, so it is important to ensure the minimum number of boilers are operating at any one time to satisfy variable system loads.

Key areas to inspect include the motorised isolating valves (two-port valves) on each boiler to ensure they are working correctly and avoid unnecessary energy consumption due to boiler flow temperature dilution problems. The most efficient boiler is the one that is not firing!

- Prevent Dry Cycling

Boiler dry cycling is an inherent problem found in all boilers of any size and age. Early attempts to overcome dry cycling either created a predetermined firing period (time delays) or lowered the boilers’ set points based on a boiler return temperature.

Both of these measures impacted on ambient room temperatures and comfort levels and potentially reduced hot water storage temperatures, increasing the risk of Legionella. Both measures will also conflict with existing BMS or weather compensation controls.

In recent years technology has been developed to prevent dry cycling without reducing the boilers’ set points or ambient room temperatures. This technology optimises the load of individual boilers using real time analysis of each boiler’s temperature profiles, rather than using predicted or historical firing patterns.

By analysing real-time flow and return temperature profiles for each boiler, it differentiates between general heating demands and false demands created by standing losses that lead to dry cycling This technology also integrates seamlessly with existing controls such as BMS, weather compensation and boiler sequencing.

- Regularly check boiler operating times

Check that time clocks are correctly set for required operating/occupancy times, with different settings for weekends and holidays, and are adjusted when the clocks move between GMT and BST. Building optimisation/weather compensation controls must also be correctly commissioned for required space temperatures and occupancy times and sensors should be regularly calibrated.

- De-scale the boilers and clean the flues

Boilers with scale/sludge build-up waste energy through reduced heat transfer efficiency so it’s important to check for correct chemical dosing and for leaks that may result in untreated water continuously refilling the system. This ‘make up’ water increases scaling and reduces the overall system temperature, thus wasting energy.

Flues should also be cleaned regularly; dirty boiler flue-ways can decrease boiler efficiency by more than 10%.

More to follow … steps 6 – 10